Big Dig Disaster

The Incident: July 10, 2006 – A Preventable Tragedy

On July 10, 2006, at approximately 11:01 p.m. eastern daylight time, a 1991 Buick passenger car carrying a 46-year-old driver and his 38-year-old wife, Milena Del Valle, was traveling eastbound in the Interstate 90 connector tunnel in Boston, Massachusetts, en route to Logan International Airport. As the car approached the end of a curved section of the tunnel, a concrete ceiling panel, estimated to weigh 26 tons (24,000 kg), detached and fell onto the vehicle. Milena Del Valle was fatally injured, and her husband sustained serious injuries. The National Transportation Safety Board (NTSB) launched an investigation into the collapse.

The NTSB determined that the probable cause of the collapse was the “creep” of the epoxy adhesive used to bond the anchor bolts that suspended the ceiling panels. At the collapse site, 20 anchors were found to have pulled out of the tunnel roof. The NTSB report concluded that this accident “could have been avoided” if proper materials and oversight had been maintained throughout the project. The incident led to immediate tunnel closures, extensive repairs, and multiple investigations.

Project Background: The Ambitious Big Dig

The Central Artery/Tunnel Project, commonly known as the Big Dig, was designed to replace Boston’s elevated Central Artery with an underground highway system. The goal was to reduce severe traffic congestion and reconnect neighborhoods that had been separated by outdated infrastructure. Initially projected to cost $2.8 billion, the project’s final price soared to $14.78 billion due to delays, design changes, and cost overruns (NBC News). Some estimates, including those factoring in interest payments, place the total cost at $24.3 billion (WBUR Boston).

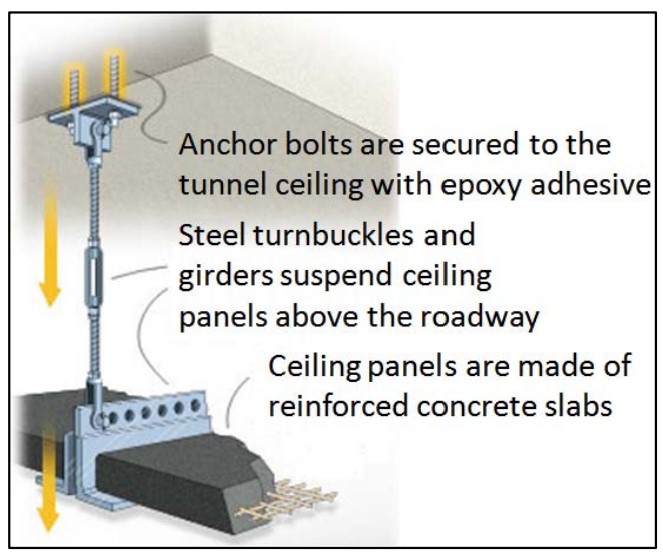

The design and construction of the tunnel ceiling involved suspending precast concrete panels using steel anchor bolts bonded into the concrete roof arch with epoxy adhesive. The proper selection and application of this adhesive were critical for the long-term stability of the ceiling system. However, the epoxy used lacked sufficient creep resistance, leading to gradual deformation and eventual failure, which caused the anchors to detach and the ceiling to collapse

Technical Analysis: The Fatal Epoxy Problem

Material Specification vs. Actual Installation: A Critical Deviation

The investigation revealed that the collapse was primarily caused by using an epoxy adhesive that was unsuitable for sustained loads. In simple terms, the adhesive lacked the necessary resistance to “creep” – the gradual deformation under long-term stress. Instead of using the specified standard-set epoxy (Powers Fasteners’ Type IV), which was designed for long-term structural applications, a fast-set epoxy (Powers Fasteners’ Power-Fast Set) was installed. This substitution, made without a proper evaluation of its long-term performance under sustained overhead loading, ultimately proved fatal.

| Property | Specified Standard-Set Epoxy (Powers Fasteners’ Type IV) | Used Fast-Set Epoxy (Powers Fasteners’ Power-Fast Set) |

|---|---|---|

| Creep Resistance | Adequate for sustained loads | Poor resistance to long-term loads (Critical Oversight) |

| Cure Time | Typically 24 hours | Faster cure time (e.g., 15 minutes) |

| Design Life Suitability | Suitable for long-term structural applications (75+ years) | Not suitable for sustained loads; intended for temporary/short-term loads |

| Load Rating | Structural/Permanent load capacity | Limited to temporary/short-term loads (Misapplied Material) |

| Cost Considerations | — | Chosen potentially for perceived installation speed and cost savings, but ultimately led to massive subsequent costs. |

Understanding Creep in Polymeric Materials: The Hidden Structural Threat

Creep is a gradual, irreversible deformation that occurs when a material is subjected to constant stress over time. In polymeric adhesives like epoxy, molecular chains slowly shift and elongate, even under loads well below the material’s yield strength. If engineers fail to account for creep behavior, especially in high-stress applications, it can lead to catastrophic structural failure.

The Big Dig tunnel collapse was a direct result of epoxy creep failure. The National Transportation Safety Board (NTSB) determined that the epoxy anchor adhesive used in the tunnel had poor creep resistance, leading to the gradual weakening of the anchor system. Over time, the epoxy deformed, causing the anchors to detach and ultimately leading to the ceiling panel collapse.

Alarmingly, Powers Fasteners had already conducted independent creep tests on its fast-set epoxy as early as 1995 and 1996, which demonstrated its unsuitability for sustained load applications. In 1999, the company went even further, officially advising its clients that “all amine-based fast-set epoxies do not meet the elevated temperature creep requirements by a significant margin” and were only recommended for short-term loading due to seismic and wind events.

Despite these explicit warnings, the fast-set epoxy was still chosen for use in the I-90 tunnel ceiling—a decision that would prove disastrous. This case highlights a fundamental failure in risk assessment, material selection, and engineering oversight, implicating multiple parties involved in the project.

Additional Contributing Factors: Beyond Just Epoxy

While epoxy creep was identified as the primary cause of the failure, the NTSB investigation uncovered several additional engineering flaws that further weakened the anchor system. These overlooked factors contributed to the catastrophic collapse and emphasized the need for stronger quality assurance protocols in tunnel construction.

- Insufficient Epoxy Filling (Voids): Many failed anchor holes contained voids, meaning the epoxy resin did not fully fill the drilled space around the anchor bolts. This significantly reduced the effective bonding area and load capacity. Post-accident inspections revealed voids in nearly all failed anchors, with 19 of the 20 examined anchors showing incomplete epoxy coverage

- Over-tightening of Anchor Nuts: Investigators found that some anchor nuts were tightened beyond the recommended torque levels. This excessive force may have initially weakened the epoxy bond, although its role in accelerating creep failure was secondary compared to the adhesive’s inherent instability under long-term stress.

- Plastic Setting Caps: Anchor rods were fitted with plastic setting caps designed to centralize the bolts during installation. However, these caps inadvertently prevented full embedment of the anchor nut and washer into the epoxy, weakening the connection. Engineering analysis suggested this reduced overall load capacity by approximately 10%.

These failures, combined with the epoxy’s poor creep resistance, created a perfect storm of structural vulnerabilities that ultimately led to the collapse. The NTSB concluded that a more robust quality assurance program—one that prioritized creep resistance testing, thorough epoxy application, and proper anchor installation—could have prevented this disaster.

Failure Timeline: A Chronicle of Oversight

During this period, Powers Fasteners’ Power-Fast Set epoxy was substituted for the specified standard-set product to suspend the tunnel ceiling panels. This decision was made without a proper engineering review of the epoxy’s ability to withstand sustained loads.

Alarmingly, in 1999, concerns were raised about the Big Dig tunnel ceiling anchors when five bolts failed during testing—an early warning sign of possible failure. Despite this, project managers declined further testing, missing a crucial opportunity to prevent disaster.

The tunnel officially opened to traffic, but hidden dangers lurked. The fast-set epoxy began creeping under the relentless weight of the 26-ton ceiling panels. Engineers had already identified anchor displacement in earlier inspections, yet neither Modern Continental nor Bechtel/Parsons Brinckerhoff implemented a monitoring program.

The Massachusetts Turnpike Authority (MTA) also failed to establish an effective tunnel inspection system that could have detected the ongoing creep problem before it became critical.

As the epoxy continued to deteriorate, its creep rate accelerated, leading to visible displacement in some anchor bolts. These were clear warning signs of imminent failure, yet the existing inspection protocols failed to flag the risk.

The Massachusetts Turnpike Authority (MTA) did not implement a comprehensive monitoring program, and construction and design consultants overlooked the severity of the displacement concerns. At this point, failure was no longer a question of “if” but “when”.

At 11:01 p.m., multiple anchor points failed simultaneously, causing a 26-ton concrete panel to detach from the tunnel ceiling. It collapsed onto a passing vehicle, tragically killing Milena Del Valle and severely injuring her husband.

The collapse exposed years of overlooked engineering flaws, triggering widespread public outcry. The NTSB launched an in-depth investigation, confirming that poor material selection, inadequate oversight, and ignored warning signs contributed to this avoidable disaster.

Consequences: Financial and Ethical Reckoning

The financial repercussions of the I-90 tunnel ceiling collapse were staggering. The MTA paid $6 million in restitution to the Del Valle family, while Powers Fasteners settled for $16 million. Bechtel/Parsons Brinckerhoff, the joint venture overseeing design and construction, agreed to a $450 million settlement to cover widespread flaws throughout the entire Big Dig project. (NBC News).

Beyond the monetary consequences, the ethical failures were equally severe. The NTSB report criticized material selection, quality assurance, and oversight failures. Criminal charges were initially brought against a Powers Fasteners executive for manslaughter, though they were later dropped.

This tragedy forced the construction industry to reevaluate safety protocols, material testing procedures, and ethical responsibilities. It became a painful reminder that public safety must never be compromised for cost efficiency or convenience.

Lessons Learned: Prioritizing Safety and Due Diligence

The I-90 tunnel ceiling collapse serves as a stark reminder of critical lessons for engineers, project managers, and oversight bodies:

Material Selection and Testing

Always verify that materials are appropriate for their intended use, especially under sustained loads and environmental conditions. Comprehensive, independent testing for properties like creep resistance is non-negotiable for long-term structural applications. Never substitute specified materials without thorough engineering review and validation.

Rigorous Quality Assurance & Control

Implement robust QA/QC programs that cover every stage of a project, from design and material procurement to installation and post-construction monitoring. Ensure proper installation techniques are followed and verified, and that all project personnel understand the critical importance of adhering to specifications.

Importance of Early Warning Signs

Any detected anomalies, such as unexpected displacements or movements in structural components, must be thoroughly investigated immediately. Dismissing “slight movements” or other warning signs as “normal” can lead to catastrophic consequences. Establish clear protocols for reporting, investigating, and remediating such issues.

Ethical Responsibility in Engineering

Engineers and project stakeholders have an ethical obligation to prioritize public safety above schedule pressures or cost savings. This includes transparent communication about material limitations, potential risks, and observed deficiencies. A culture that encourages reporting problems without fear of reprisal is essential.

Comprehensive Inspection & Monitoring

For large-scale infrastructure, establish and consistently execute long-term inspection and monitoring programs. These programs should utilize advanced techniques to detect subtle material degradation or structural shifts before they escalate into failures. Regular, thorough inspections are crucial for ensuring the ongoing safety and integrity of civil structures.

Accountability and Oversight

Clear lines of accountability must be established for all parties involved in a project, from designers and contractors to oversight agencies. Independent oversight bodies play a vital role in ensuring compliance with safety standards and best practices. Failures of oversight can have devastating human and financial costs.

One Response